Industry

By Admin

By Admin

Inside The Process Of Making Computer Jacquard Elastic Bands

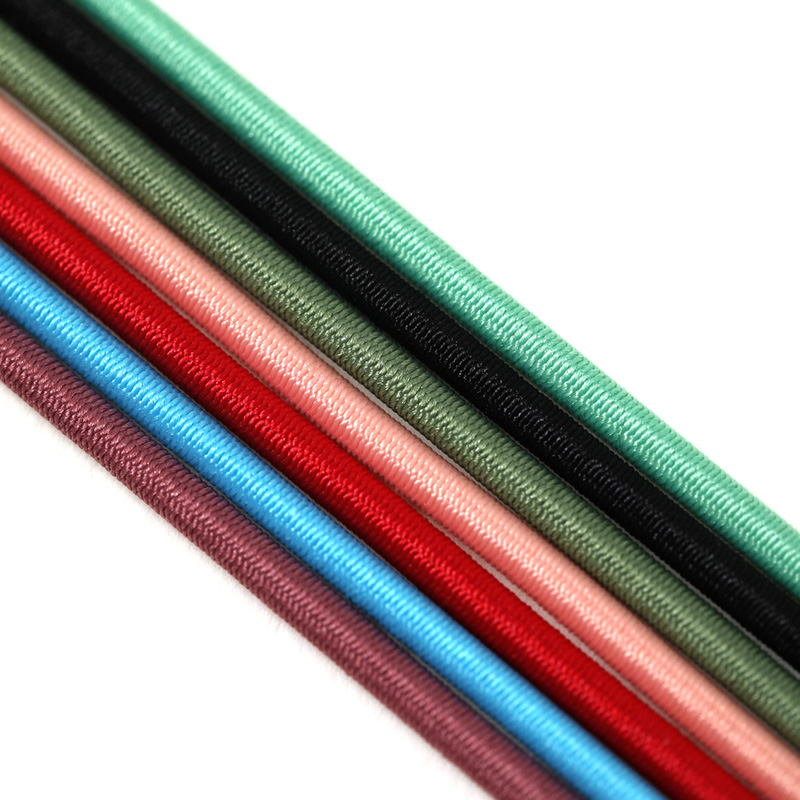

Computer jacquard elastic bands have become a popular choice in the garment and accessory industries, valued for their versatility, durability, and the ability to feature detailed woven designs. Understanding how these bands are made offers insight into the craftsmanship and technology involved. Central to this production are woven elastic tape, anti slip elastic band, and knitting elastic tape — each playing a crucial role in the final product's performance.

The journey begins with the selection of raw materials. High-quality yarns, typically polyester or nylon mixed with elastic fibers like spandex, form the foundation of the woven elastic tape. This tape is the core structure of jacquard elastics, providing the stretch and recovery properties essential for waistbands, cuffs, and other garment features. The woven elastic tape ensures that the fabric maintains its shape over repeated use, offering reliable flexibility.

Once the yarns are prepared, they are fed into specialized jacquard weaving machines. These machines use computer programming to control intricate patterns woven directly into the elastic band. This is where the term “computer jacquard” comes from: the combination of traditional jacquard weaving techniques with computerized pattern control. The result is an elastic band that is not only functional but also visually appealing, with designs that can range from simple stripes to complex logos and motifs.

During weaving, attention is given to the knitting elastic tape component. While the base structure is woven, the incorporation of knitting elastic tape elements can enhance softness and comfort. This hybrid approach blends the strength of woven tape with the stretch and feel of knitted elastic, catering to different garment needs. For example, sportswear may benefit from the addition of knitting elastic tape for improved comfort and flexibility during physical activity.

The anti slip elastic band is another important feature often integrated during production. This element is designed to improve grip and prevent the elastic from sliding or rolling in place. Manufacturers achieve this by adding silicone strips or textured surfaces onto the underside of the woven elastic tape. The anti slip elastic band feature is especially useful in activewear and undergarments where maintaining position without restricting movement is key.

Quality control checks are performed at various stages to ensure that the woven elastic tape meets the necessary standards. Tests for elasticity, recovery rate, and durability are critical to producing an elastic band that can withstand repeated stretching and washing. The anti slip elastic band is also examined for adhesion strength to confirm that it will stay effective throughout the product's lifecycle.

After the weaving and finishing processes, the elastic bands are cut to the desired widths and lengths, ready to be shipped or used in garment manufacturing. Throughout this entire process, the balance between functionality and aesthetic appeal is maintained. The combination of woven elastic tape, anti slip elastic band, and knitting elastic tape ensures that the final jacquard elastic bands perform well while adding a decorative touch.

These three components—woven elastic tape, anti slip elastic band, and knitting elastic tape—are key to the versatility and functionality of computer jacquard elastic bands. By combining them in the manufacturing process, producers create elastic bands that meet the demands of both fashion and performance markets. Understanding this process helps appreciate the complexity and skill involved in creating these essential garment accessories.

English

English Español

Español عربى

عربى Tiếng Việt

Tiếng Việt